NovaTech Space Systems: Rocket Design

Summary:

- Rocket Design Mentor: Dr. Justin Little

- Rocket Design Team: Felicity Cundiff, Grayson Atwell, Mack Rowan Howard, Andrew Truong, Kai Alden Laslett-Vigil, and Daniel Molidor

- 1. NovaTech Rocket Prop Presentation: Here

- 2. NovaTech Rocket Prop Report: Here

A group of venture capitalists expressed interest in funding a network of small satellites to provide satellite internet coverage globally. They tasked our team with designing a low-cost rocket featuring a reusable first stage capable of deploying a single 1,000 kg satellite into a 500 km altitude low-Earth orbit (LEO). Key design requirements included delivering the payload efficiently, minimizing costs, and ensuring reusability of the first stage.

-

NOVA 1 rocket project:

- Initiated in response to venture capitalists' challenge for a cost-effective LEO satellite deployment solution.

- Focuses on designing a gas turbine engine core for airbreathing propulsion with emphasis on efficiency and turbine inlet temperatures.

- Engine components (compressor, combustor, turbine) crucial for engine efficiency and emissions control.

- Design decisions prioritize efficiency, cost-effectiveness, and performance at designated design points.

- Engineered to deliver a 1,000 kg payload to a 500 km Low Earth Orbit (LEO) with a ∆V budget of 9 km/s.

- Boasts a launch cost of $13.5 million per launch, demonstrating cost-effectiveness.

- Performance attributes include a launch mass of 15,266 kg, ∆V of 9.175 km/s, burnout altitude of 545 km, and burn time of 439.6 seconds.

-

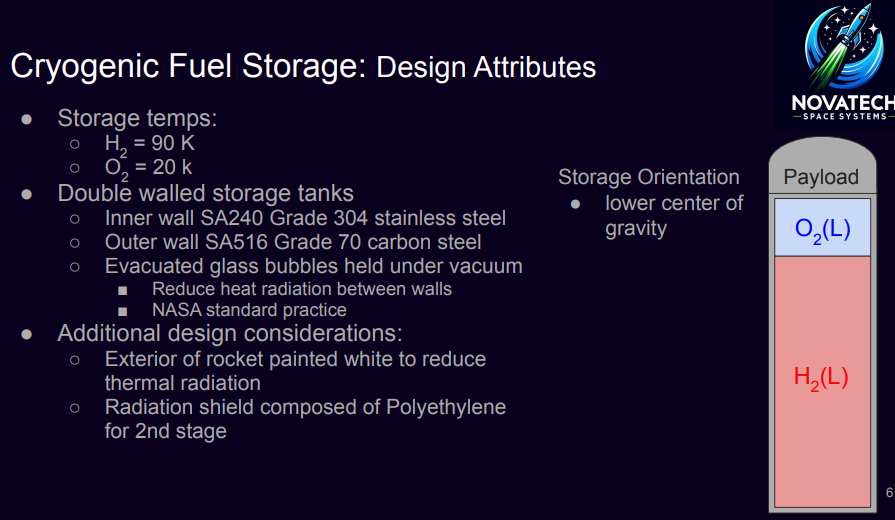

To ensure optimal performance and minimize propellant loss:

- The NOVA 1 employs a sophisticated cryogenic fuel storage system.

- Double-walled vacuum storage tanks made from stainless steel and carbon steel house liquid hydrogen and oxygen.

- Designed to mitigate boil-off a nd maintain propellant integrity throughout the mission, drawing inspiration from NASA's Kennedy Space Center practices.

-

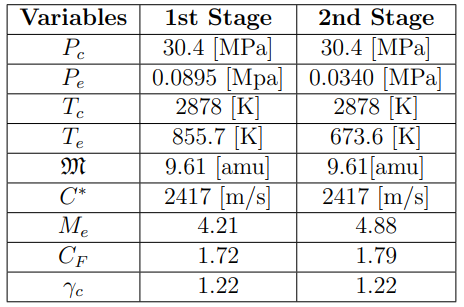

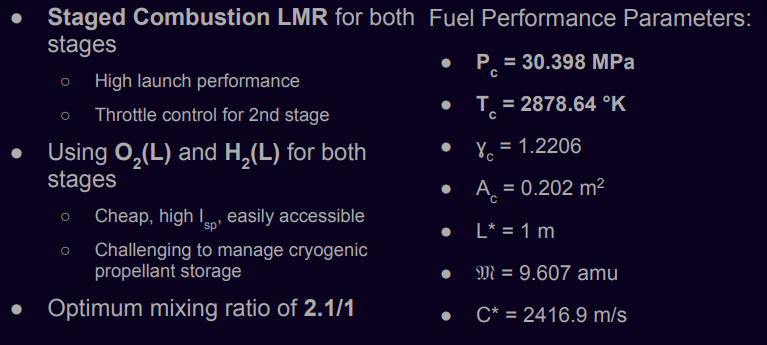

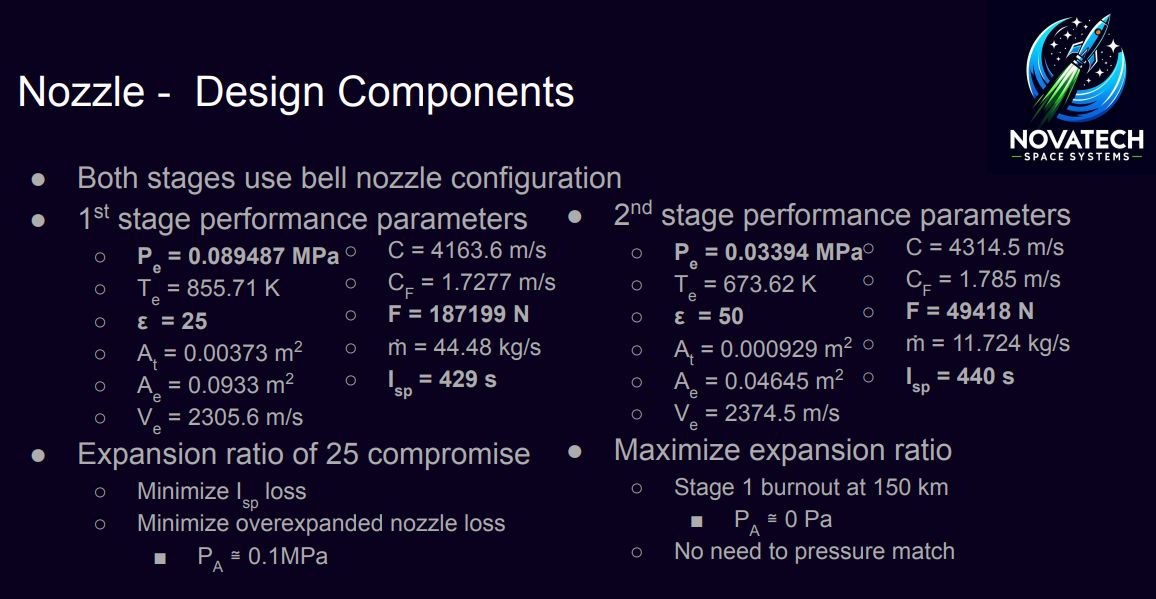

Staged Combustion Liquid Rocket Motors (LMR) using Oxygen (O2) and Hydrogen (H2):

- - Chosen for both stages due to their cost-effectiveness and high specific impulse (Isp).

-

A meticulous technical approach guided the NOVA 1 project:

-

Storage Temperatures:

- - Liquid Hydrogen: Stored at 20◦K for optimal performance and stability.

- - Liquid Oxygen: Stored at 90◦K to maintain its liquid state during storage and operation.

-

Storage System Design:

- - Utilizes a double-walled vacuum system for cryogenic propellants.

- - Inner wall: Constructed from SA240 Grade 304 stainless steel for structural integrity and corrosion resistance.

- - Vacuum between walls filled with evacuated glass bubbles under mild vacuum to minimize heat transfer via radiation.

- - Outer wall: Made of SA516 Grade 70 carbon steel, primarily serving as an insulating layer to reduce heat ingress.

-

Inspiration and Additional Design Considerations:

- - Draws design inspiration from NASA Kennedy Space Center's proven large-scale hydrogen storage tanks.

- - Exterior of the rocket body painted white to reflect solar radiation and reduce absorption, crucial for missions launched from equatorial regions.

- - Second stage incorporates a polyethylene radiation shield to further mitigate the effects of solar radiation beyond the atmosphere.

-

Tank Orientation and Specifications:

- - Tanks in both stages oriented with the Oxygen tank above the Hydrogen tank to lower the rocket's center of gravity as propellants are consumed.

- - All storage tanks designed cylindrically with an inner radius of 2 meters for structural efficiency and uniform distribution of propellants.

- - First stage: Holds 6469.56 kg of Hydrogen and 3080.742 kg of Oxygen.

- - Second stage: Contains 1744.829 kg of Hydrogen and 830.871 kg of Oxygen.

- - Total estimated height of the propellant tanks reaches 9.5 meters, optimizing volume and space efficiency within the rocket design.

-

-

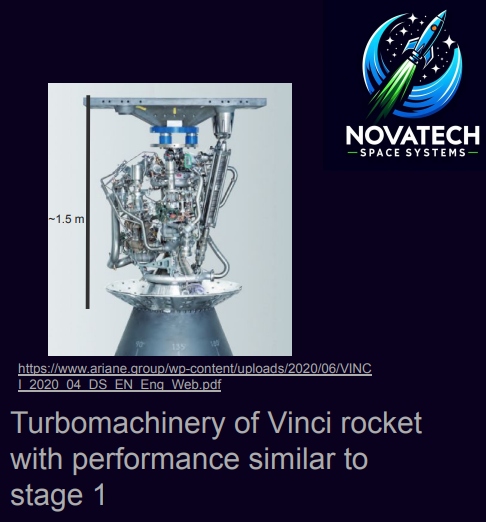

Integral to the rocket's propulsion system:

- - Turbomachinery efficiently delivers propellants to the combustion chamber.

- - Staged combustion LRMs ensure precise fuel delivery and combustion efficiency.

-

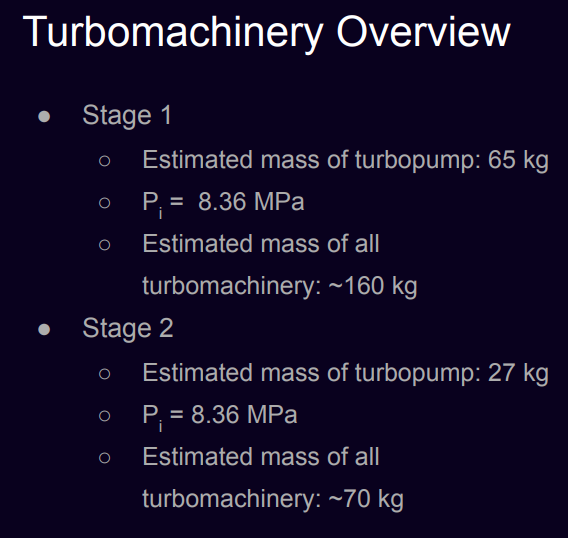

Process of Sizing and Optimizing Turbopumps:

-

We began by calculating the exit pressures of the fuel and oxidizer. The exit pressure of the fuel \( P_{fe} \) and the oxidizer \( P_{oxe} \) were determined using the following equations:

- \( P_{fe} = (1 + 0.82)P_c \), where \( P_c \) is the chamber pressure set to 300 atm, yielding \( P_{fe} = 546 \, \text{atm} \).

- \( P_{oxe} = (1 + 0.12)P_c \), yielding \( P_{oxe} = 336 \, \text{atm} \).

-

Next, the pressure of the gas generator combustion chamber \( P_{cgg} \) was estimated using the minimum pressure from the oxidizer exit pressure:

- \( P_{cgg} = \frac{P_{oxe}}{1.02} \), yielding \( P_{cgg} = 329.4 \, \text{atm} \).

-

We then estimated the turbine exit pressure \( P_{t,e} \) using the ambient pressure \( P_a \) and the specific heat ratio \( \gamma_{gg} \) of the gas generator, which was calculated as follows:

- \( P_{t,e} = P_a \left( \frac{\gamma_{gg} + 1}{2} \right)^{\frac{\gamma_{gg}}{\gamma_{gg} - 1}} \), yielding \( P_{t,e} = 1.84 \, \text{atm} \).

-

To determine the power required for the turbopump's turbine, we used the equation for turbine power, incorporating the mass flow rate \( \dot{m}_{gg} \), turbine efficiency \( \eta_t \), specific heat at constant pressure \( C_{p,gg} \), and the gas generator combustion chamber temperature \( T_{cgg} \).

- \( \text{Turbine Power} = \dot{m}_{gg} \eta_t C_{p,gg} T_{cgg} \left[ 1 - \left( \frac{P_{t,e}}{P_{cgg}} \right)^{\frac{\gamma_{gg} - 1}{\gamma_{gg}}} \right] \)

-

We then solved for the unknown mass flow rate of the gas generator \( \dot{m}_{gg} \) using the following equation, which relates the power required by the turbopump to the pressure drops and densities of the propellants:

- \( \text{Turbine Power} = \left( \dot{m}_f + \frac{\dot{m}_{gg}}{1 + r_{gg}} \right) \frac{\Delta P_f}{\rho_f \eta_{pf}} + \left( \dot{m}_{ox} + \frac{r_{gg} \dot{m}_{gg}}{1 + r_{gg}} \right) \frac{\Delta P_{ox}}{\rho_{ox} \eta_{pox}} \)

where \( \Delta P_f \) and \( \Delta P_{ox} \) are the pressure increases for the fuel and oxidizer, and \( \rho_f \) and \( \rho_{ox} \) are their respective densities.

-

The results for the mass flow rates of the gas generator were found to be:

- \( \dot{m}_{gg1} = 5.035 \, \text{kg/s} \) for stage 1

- \( \dot{m}_{gg2} = 1.255 \, \text{kg/s} \) for stage 2

-

The power required for the turbopumps was calculated as follows:

- First stage: \( 21198 \, \text{kW} \)

- Second stage: \( 5283.7 \, \text{kW} \)

-

We estimated the torque for each stage using the equation:

- \( \tau = \frac{\text{Turbine Power}}{\omega} \), where \( \omega = 50000 \, \text{rad/s} \).

- First stage torque: \( 423.96 \, \text{N} \cdot \text{m} \) (312.69 ft*lbs)

- Second stage torque: \( 105.67 \, \text{N} \cdot \text{m} \) (77.940 ft*lbs)

-

Finally, the weight of the turbopumps was calculated using the torque values:

- \( W = 5.26 \tau^{0.638} \)

- First stage: 205.5 lbs (93.21 kg)

- Second stage: 84.71 lbs (38.42 kg)

-

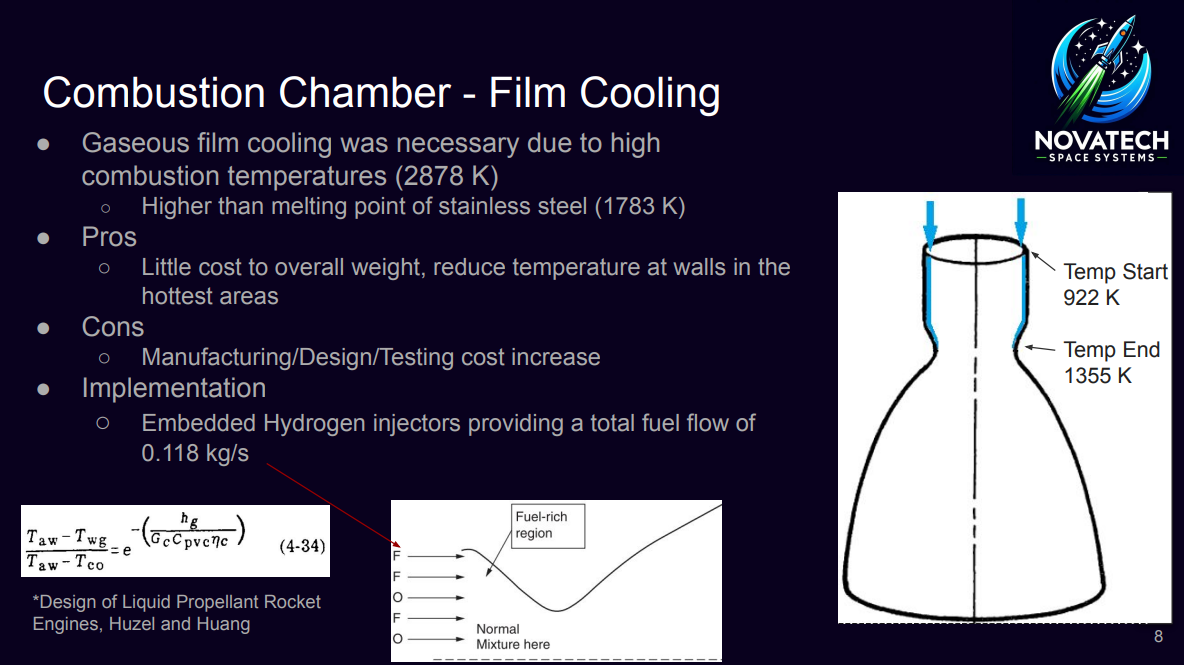

- - To manage the high combustion chamber temperatures (2878 K) and prevent melting the stainless steel combustion chamber (1783 K), gaseous film cooling is implemented in the design.

- - Hydrogen supplied by the turbine is used for this task along with the outer parameter of injectors being fuel only.

- - The starting temperature of this fluid is 922 K and enough flow rate of hydrogen will keep it to a maximum of 1355 K up to the throat section. 1355 K was chosen for margin of safety and integrity of the steel.

- - The theoretical equation from Hatch and Papell is used to find out the film coolant weight flow rate per unit area:

\[ \frac{{(T_c - T_{wg})}}{{(T_c - T_{co})}} = e^{-\left(\frac{{h_g}}{{G_c \cdot C_{p,v}}}\right) \cdot \eta_c} \] - This equation is then used to calculate 0.118 kg/s of extra fuel during flight to maintain ideal temperatures of the wall temperature. Due to both stages being similar, this applies to both stages.

- Cooling Selection: We chose a single-pass regenerative cooling system for our rocket, considering initial parameters such as pressure, mass, chamber conditions, and cooling system specifics (equivalent diameter, channel dimensions, wall thickness, and fuel flow rate).

- Coolant Jacket: The number of cooling channels (N) and mass flow rate per channel (\( \dot{m}_{chan} \)) were determined:

\( \dot{m}_{chan} = \frac{1}{N} \cdot mf \)

\( N = \frac{\pi}{\sqrt{De} + 0.8(d + 2tw)} \) (Eq. 14) - Heat Transfer: Heat transfer management is critical for optimal performance and preventing thermal damage. Thermal energy exchange between gas and wall surfaces is represented by:

\( q' = hg \cdot (Tr - TW_g) \) (Eq. 15) - Gas-side wall temperature (TW_g) stabilized at 2602.4952 K after 9 iterations. The convective heat transfer coefficient (hg) was iteratively calculated using Newton-Raphson method and Nusselt number, with liquid-side wall temperature (TW_l) stabilizing at 2501.7347 K after 2 iterations:

\( Nu = 0.023 \times (Pr^{0.3}) \times (M^{0.33}) \)

\( hg = Nu \cdot \frac{kgas}{De} \) (Eq. 16) - Exploration of controlled reentry and landing capabilities for the first stage, utilizing excess ΔV to enhance reusability.

- Optimization of the first stage design, including pressure matching to sea level conditions and implementation of stability control mechanisms such as fins or gimbling nozzles.

- Structural analysis of the combustion chamber and storage tanks to determine optimal wall thickness for containing high pressures.

- Exploring the use of passive cooling techniques in the nozzle design to reduce manufacturing and operational costs.

Introduction and Background:

Technical Approach:

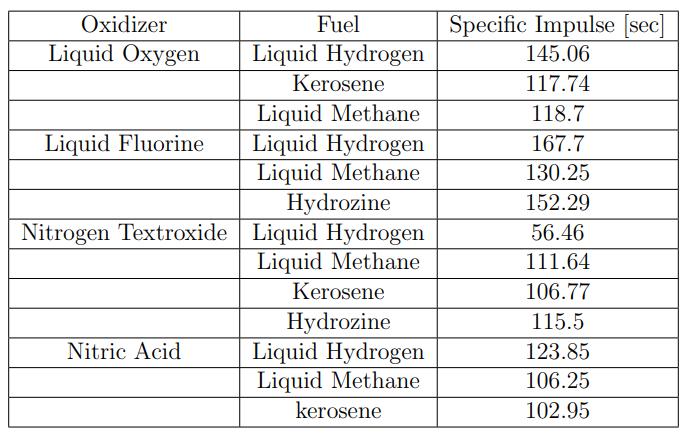

Fuel Choice:

Cryogenic Fuel Storage:

Turbomachinery:

Combustor - Film Cooling:

Regenerative Cooling

Regenerative cooling system Code:

clc

clear

close all

% Rocket parameters

P_i = 303.98 * 10^5; % Initial pressure [Pa]

M = 9.607 * 1.66054e-27; % Mass of H2 molecule [kg]

Pc = 303.98 * 10^5; % Chamber pressure [Pa]

Ve = 2374.5; % Exit velocity [m/s]

Pe = 0.33994 * 10^5; % Exit pressure [Pa]

C = 4314.1; % Speed of sound [m/s]

Tc = 2878.64; % Chamber temperature [K]

C_star = 2416.9; % Characteristic velocity [m/s]

CF = 1.785; % Thrust coefficient

gamma_c = 1.2206; % Specific heat ratio

At = 0.00373;

% Regenerative cooling system parameters

De = 0.0933; % Equivalent diameter [m]

d = 0.0212; % Channel diameter [m]

tw = 0.00373; % Channel wall thickness [m]

mf = 44.48; % Fuel mass flow rate [kg/s]

% Step 1: Calculate N and mchan

N = (pi^(1/2)*De + 0.8*(d + 2*tw)) / (d + 2*tw);

mchan = mf / N;

% Step 2: Initialize i

i = 1;

% Step 3: Begin stepping down tube/channel

i = i + 1;

% Step 4: Guess the wall temperature on gas side, Twgi.

tolerance = 1e-6; % Tolerance for convergence

max_iterations = 100; % Maximum number of iterations

% Initial guess for Twgi

Twgi_guess = 300; % Initial guess for Twgi [K]

% Iterative loop to guess Twgi

for iteration = 1:max_iterations

% Calculate functions f(Twgi) and its derivative

[f_Twgi, df_Twgi] = calculate_functions(Twgi_guess);

% Twgi using Newton-Raphson method

Twgi_new = Twgi_guess - f_Twgi / df_Twgi;

% Check convergence

if abs(Twgi_new - Twgi_guess) < tolerance

Twgi = Twgi_new;

fprintf('Twgi converged after %d iterations.\n', iteration);

break;

end

% Update guess for next iteration

Twgi_guess = Twgi_new;

% Check for maximum iterations reached

if iteration == max_iterations

warning('Maximum iterations for Twgi reached without convergence.');

end

end

% Step 5: Calculate hg then q' = hg * (Tr - Twgi)

T_chamber = Tc; % Chamber temperature [K]

p_chamber = Pc; % Chamber pressure [Pa]

Pr = 0.7; % Prandtl number

Nu = 0.023 * (Pr^0.3) * (M^0.33); % Nusselt number

k_gas = 0.03; % Thermal conductivity of gas [W/(m*K)]

% Calculate hg using correlation

hg = Nu * k_gas / De; % Convective heat transfer coefficient [W/(m^2*K)]

% Calculate heat transfer rate q'

Tr = T_chamber; % Temperature of the gas [K]

q_prime = hg * (Tr - Twgi); % Heat transfer rate [W/m^2]

% Step 6: Calculate Twli from conduction through the wall, q = k * (Twgi - Twli) / tw

% Thermal conductivity of the wall material [W/(m*K)]

k_wall = 25; % Example value, replace with actual value for your material

% Initial guess for Twli

Twli_guess = 2500; % Example guess, replace with appropriate initial guess

% Define convergence criteria

tolerance_twli = 1e-6; % Tolerance for convergence

max_iterations_twli = 1000; % Maximum number of iterations

% Iterative loop to calculate Twli

for iteration_twli = 1:max_iterations_twli

% Calculate q from the previous step (Step 5)

q_wall = q_prime; % Heat transfer rate through the wall [W/m^2]

% Calculate Twli using conduction equation

Twli_new = Twgi - q_wall * tw / k_wall;

% Check convergence

if abs(Twli_new - Twli_guess) < tolerance_twli

Twli = Twli_new;

fprintf('Twli converged after %d iterations.\n', iteration_twli);

break;

end

% Update guess for next iteration

Twli_guess = Twli_new;

% Check for maximum iterations reached

if iteration_twli == max_iterations_twli

warning('Maximum iterations for Twli reached without convergence.');

end

end

% Step 7: Compute hl based on Tl(i-1) (temperature in previous segment)

T_l_previous = 400; % Temperature in previous segment [K]

Pr_l = 0.7; % Prandtl number for the liquid

Nu_l = 0.023 * (Pr_l^0.3); % Nusselt number for the liquid

k_l = 0.6; % Thermal conductivity of the liquid [W/(m*K)]

% Calculate hl using correlation

hl = Nu_l * k_l / De; % Convective heat transfer coefficient for the liquid [W/(m^2*K)]

% Display hl

fprintf('Convective heat transfer coefficient for the liquid (hl): %.4f W/(m^2*K)\n', hl);

% Define an initial value for Tl_current

Tl_current = 300;

% Step 10: Obtain a new liquid temperature in the ith segment

rho_l = 800; % Liquid density [kg/m^3]

mu_l = 0.0003; % Liquid viscosity [Pa*s]

q_dAi = 100; % Example value [W/m^2]

bi = 0.05; % Example value [m]

Delta_Si = 0.1; % Example value [m]

Pl_current = 1.0e5; % Example value [Pa]

di = 0.01; % Example value [m]

% Provided values for xi_next and xi_current

xi_next = 2;

xi_current = 1;

% Calculate new liquid temperature Tl(i+1) based on the given formula

Delta_xi = xi_next - xi_current;

Tl_new = Tl_current + (1 / (mchan * Delta_xi)) * (q_dAi * bi * Delta_Si) + 2000;

% Update liquid properties based on the new temperature Tl_new

Re = mchan / (rho_l * At); % Reynolds number

if Re < 2100

cfi = 16 / Re;

elseif Re >= 5000 && Re <= 200000

cfi = 0.046 / Re^0.2;

elseif Re > 3000 && Re <= 3000000

cfi = 0.0014 + 0.125 / Re^0.32;

end

v_l = mchan / (rho_l * At); % Liquid velocity

target_pl = 296.2; % Desired liquid pressure

Pl_new = Pl_current - cfi * (Delta_xi / di) * (2 * rho_l * v_l^2);

pressure_difference = Pl_new - target_pl;

Pl_new_adjusted = Pl_new - pressure_difference;

% Step 11: Move onto the next segment or manifold % Define the total number of segments in the jacket

num_segments_in_jacket = 10;

% Define reached_end_of_jacket_or_manifold condition based on your problem's requirements

% For example, you might have a condition to check if the current segment is the last one in the jacket:

reached_end_of_jacket_or_manifold = (i == num_segments_in_jacket);

% Check if we have reached the end of the jacket or at intermediate manifolds

if reached_end_of_jacket_or_manifold

% Set manifold pressure equivalent to the local static pressure of the last segment

manifold_pressure = local_static_pressure_of_last_segment;

% Reset for the next segment or manifold

% You may need to reset variables, indices, etc., depending on your implementation

% Example:

i = i + 1; % Move onto the next segment

Twgi_guess = initial_guess_for_Twgi; % Reset the initial guess for Twgi

% Reset other variables as needed

else

% Continue to the next segment

i = i + 1;

end

% Display new liquid temperature and pressure

fprintf('New liquid temperature (Tl(i+1)): %.4f K\n', Tl_new);

fprintf('New liquid pressure (Pl(i+1)): %.4f Pa\n', Pl_new_adjusted);

% Function to calculate functions f(Twgi) and its derivative

function [f_Twgi, df_Twgi] = calculate_functions(Twgi)

% You need to define these functions based on your system equations

% This is just a placeholder

f_Twgi = Twgi^2 - 100;

df_Twgi = 2 * Twgi;

end